BIM Analyzing Tool

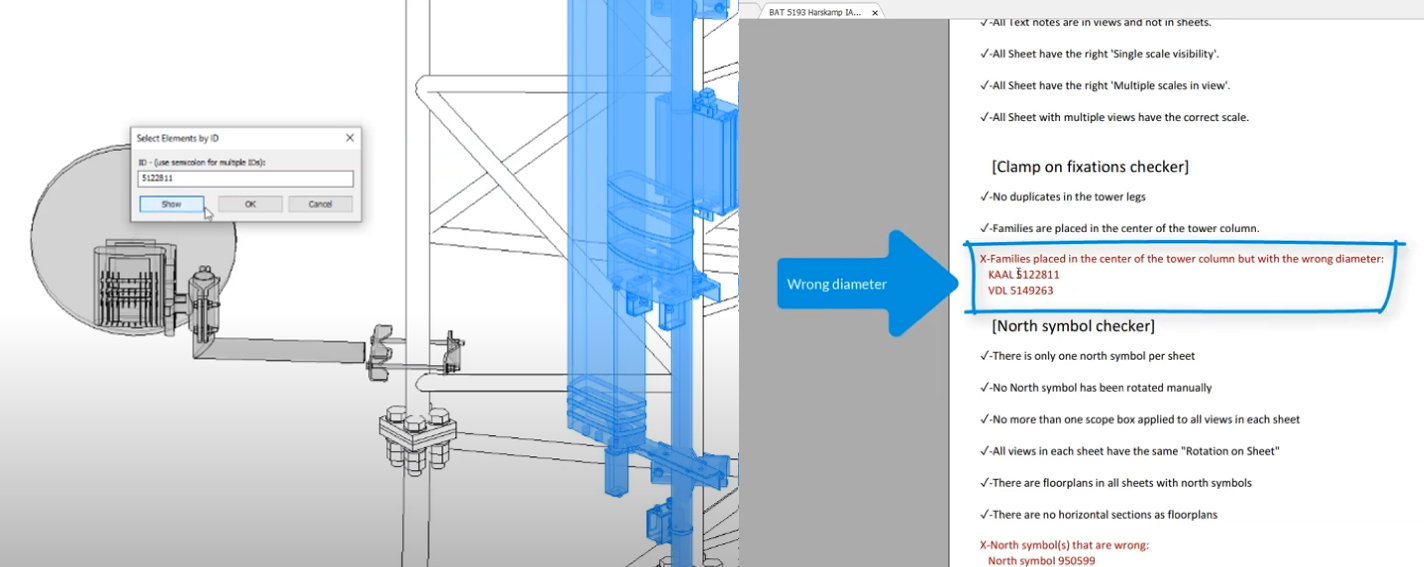

Scan to BIM and 3D modelling are becoming increasingly more popular. However, even the most experienced Revit modeler can make an occasional mistake. Small errors in Revit files can have a huge impact in being able to interact with the model down the line. Allinq Insite experienced this at first hand. When scaling the company, we needed to find a way to check a 3D model, based on specifications, before delivering it to our customers.

Therefore, we created a BIM Analyzing Tool that not only checks parameters in Revit files, but we also went a step further. When developing the BIM Analyzing tool, we soon noticed that elements were clashing, not connected, or entirely misplaced even though the parameters were correct. Therefore, we developed it to be able to assess the location of the element in the 3D space and interactions of the elements around it. With this information we can guarantee if the Revit file is modeled according to the specifications, ensuring uniformity. Furthermore, we developed an online platform where users can upload their Revit files and a report will be generated stating per Revit ID what is correct and what is not, according to the specification.

All customers have their own BIM Execution Plan. Therefore, we tailor the BIM Analyzing Tool to the specific needs of our customers, that allows them to trust their asset data. Customers of the BIM Analyzing Tool provide the platform to their suppliers of 3D models as a first barrier of verification.

The benefits of the BIM Analyzing Tool:

- Guaranteed uniformity

- Enforce BIM Execution Plans

- No rogue families

- Faster Acceptance of 3D projects

- Verified monitoring of suppliers’ 3D models

Automated engineering

Checking the Revit file on parameters, and if an object is placed correctly in the 3D space are two of our specialties. If you combine that with our other capability of placing Revit families automatically in a 3D space, after being detected in the Point cloud, [url to article] it enables Allinq Insite to go a step further into the future applications of BIM in the Engineering world! Because we can confirm if a 3D model is made according to your specification and we are able to automatically place Revit families in a 3D space, it allows us to propose designs to the engineer in a brownfield situation.

One of our customers in the energy market is partnering with us in this endeavor. We are working on automatically designing a high voltage power station, based on this principle. However, such automated engineering is only possible if both the supplier and the customer are truly willing to collaborate and share the future benefits of such a development. Allinq Insite is not a specialist on the engineering of high voltage plants. But with trust and commitment of both parties we can translate the tacit knowledge of engineers into a 3D modeling program. Improving the world step by step.

The benefits of automated engineering:

- Reduce engineering cycle time

- Hedge engineering knowledge

- Fully automate your engineering process

Verify Revit file based on security images

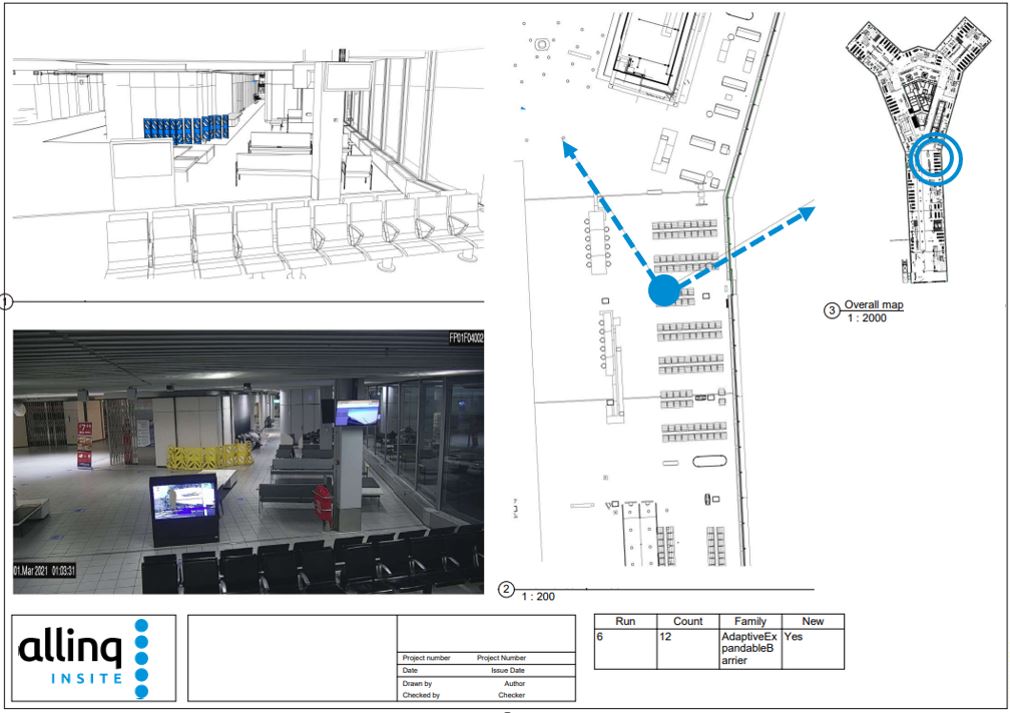

Keeping a Revit File up to date can also be achieved via images of security cameras. Allinq Insite collaborated with Schiphol, the largest Airport of the Netherlands, to find innovative solutions to unsure up to date Revit files. At large airports, many changes are being made to terminals and lounges, to accommodate as many passengers as possible, in a short period. However, after finishing one construction job, another one already starts. Making it very hard to have an up-to-date LOD200 BIM model. Airports have a hard time tracking all these construction activities, confirming if permits are approved and if passenger flow isn’t impeded by the construction work. Having an up-to-date BIM model to combine all this information is crucial to manage the airports’ operations successfully. Allinq Insite developed tooling that detects changes from images of the security cameras and places the objects in the Revit file. Creating one near time up to date source of truth.

The benefits of verifying via security images:

- No LIDAR scan required

- Utilization of existing security cameras

- Near time up to date Revit Model

Disrupting the global industry

We are Allinq Insite and we’re disrupting the global industry by digitalizing assets. Founded in the Netherlands under the Allinq Group in 2017, our roots are based in engineering. With the need for accurate 3D information, we set out to develop a Scan to BIM technology, with the requirements of engineering in mind. All the Research & Development and the execution of projects are being done with the mindset of what can be automated, will be automated. Throughout the years we were able to show customers in many different fields of applications our added value, through the highly effective Parametric as Built Revit models.

Our expertise is used for many different fields of applications that have all in common; the need of accurate As Built 3D models. Such as:

- Energy

- Construction

- Airports

- Mobile Telecom

- Fixed Telecom

Let’s meet!

Visit us at booth number 13 or at our presentation the 23rd at 14:00 ‘BIM scripting for Brown Field inventory applications’ where we will discuss the use cases of our customers and the benefits they reap so far.

Contact details

Leander Goor

+316 101 90 369